Page 1 of 2

Cast boolit dedicated seating dies.

Posted: Sat Dec 19, 2015 12:57 am

by Alpha1

I picked up on a thread on NOE bullet moulds site the guy was asking if they could make a seater die or a seater stem to match the profile of the bullet nose as dropped from the mould.

I have a couple of NOE mould. I intend to buy more one of the options they offer when you order your mould is a top punch. The top punch is normally used in the Lyman lube sizer. You push the cast boolit through the lube sizer H&I sizing die to size the boolit to the correct diameter the top punch is a perfect fit to the boolit nose shape so you do not get a ring round the top of the boolit. Seating the boolits in a normal die can leave a ring around the top of the boolit.

So I ordered extra top punches with my Moulds they are cheap as chips so why wouldn't you. The top punches they supply are aluminium so they are a doddle to machine.

I have a couple of options I would like to try. But for starters I decided to have a go at making one for my 7.62x39. The mould is a Loverin boolit that fits my rifle to a T. It works a treat. So I decided to use a modified LeWilson die for this experiment I could of made the die from scratch but I have all ready modified this one.

I made a start this evening and it went really well.

Ill post some pics later.

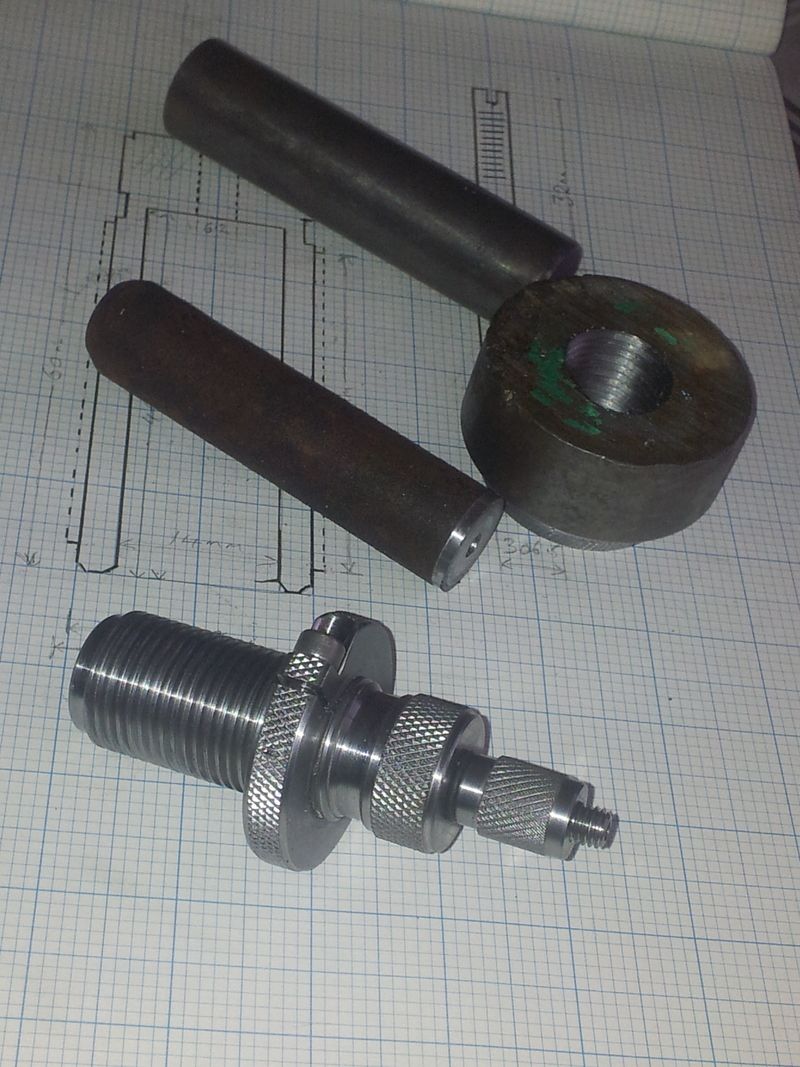

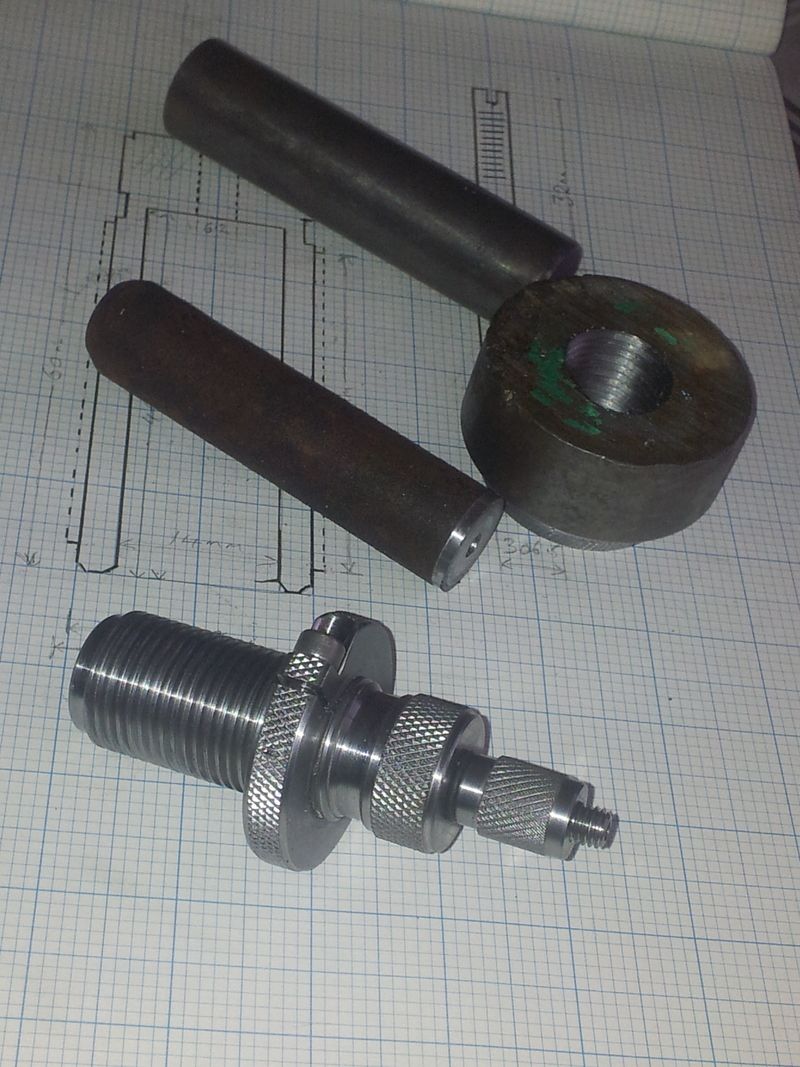

But for now this is what I started out with.

Re: Cast boolit dedicated seating dies.

Posted: Sat Dec 19, 2015 6:08 am

by dromia

I use kitchen foil as a temporary seating stem bullet nose shaper or epoxy for a permanent fix, Lee seating stems are cheap and easy to adapt, I usually use a seating die body one calibre bigger than the calibre being seated.

The M die style expander plug goes a long way to keeping the bullet aligned with the case for minimum run out.

For long range shooting with cast I use Vickerman style dies again with epoxy shaped seating stems.

A lot easier quicker and cheaper for the vast majority of us who don't or can't do machining.

Re: Cast boolit dedicated seating dies.

Posted: Sat Dec 19, 2015 11:19 am

by Alpha1

Re: Cast boolit dedicated seating dies.

Posted: Sat Dec 19, 2015 11:32 am

by ovenpaa

A worthwhile project. Have you thought about how you are going to profile the inside of the seater stem yet?

Your lathe needs a clean!

Re: Cast boolit dedicated seating dies.

Posted: Sat Dec 19, 2015 1:00 pm

by 1066

That's interesting Alpha, is that mild steel there?

I've just made a plug expander die, turned out quite well for my first attempt. Not cost effective but quite satisfying.

and video of how I made it here:

https://www.youtube.com/watch?v=MTW20NzZ-OA

Re: Cast boolit dedicated seating dies.

Posted: Sat Dec 19, 2015 2:58 pm

by Alpha1

Interesting video. Yes it is time I cleaned my lathe. I'm using mild bright steel for the seater stem. I will drill and tap the seater and screw the NOE insert into it. That way I don't have to cut the profile of the boolit. They have all ready done that for me. After I have finished this one I am going to have a go making one for conventional seating die. I had a good find at work the other day. I found a tap and die in 7/8x14 tpi(teeth par inch).

Re: Cast boolit dedicated seating dies.

Posted: Sat Dec 19, 2015 3:39 pm

by Alpha1

A worthwhile project. Have you thought about how you are going to profile the inside of the seater stem yet?

Your lathe needs a clean!

Ovenpaa out of interest how would you go about cutting the profile on the inside of the seater stem.

Re: Cast boolit dedicated seating dies.

Posted: Sat Dec 19, 2015 7:14 pm

by Alpha1

The finished article.

The seating stem on the left is the modified cast boolit seater the one on the right is for jacketed bullets the stem next to the die body is a spare.

This is the two expanders the original on top and the one I made underneath. The shiny bit is the NOE aluminium top punch I machined it to the same diameter as the seater plug drilled and tapped both bits and screwed them together so as to retain the original cast boolit nose shape. I will probably make more for my other moulds. Im now looking at making a similar jobby for a conventional seating die used on a normal bench mounted press.

This is the die in use using my Arbor press to seat cast boolits in my 7.62x39 neck sized and expanded cases.

So another success story.

hmm what's next. Oh yeah clean the lathe.

Re: Cast boolit dedicated seating dies.

Posted: Sat Dec 19, 2015 7:54 pm

by ovenpaa

Alpha1 wrote:

Ovenpaa out of interest how would you go about cutting the profile on the inside of the seater stem.

For temporary tooling I machine the cutter from silver steel to the external shape required, then cut a slot lengthways in about one third and hand grind a relief. Heat to cherry red and quench then temper and use a good quality diamond file to finish off. The cutter should end up looking a bit like a spade drill. All of the heat treatment can be done with a decent gas torch. I give the tooling a final polish and it is good to go. The interesting part with the machining is working out the optimum feed/speed to get the desired form without chatter. For more permanent tooling I use a company that can do such things in anything up to solid carbide.

Something I have been working on for a while is finding a good neat cutting oil that suits my requirements and have some super special stuff that apparently will work both for barrel work and titanium plus it is non staining. It sounds too food to be true however I will find out soon as it is due in next week

Re: Cast boolit dedicated seating dies.

Posted: Sun Dec 20, 2015 2:11 am

by Alpha1

Vickerman style dies

I googled Vickerman dies all I could find was prices but no information on sizes etc . Looking at the pictures posted I guess I could knock them out easy enough.